MC_GearIn (FB)

FUNCTION_BLOCK MC_GearIn

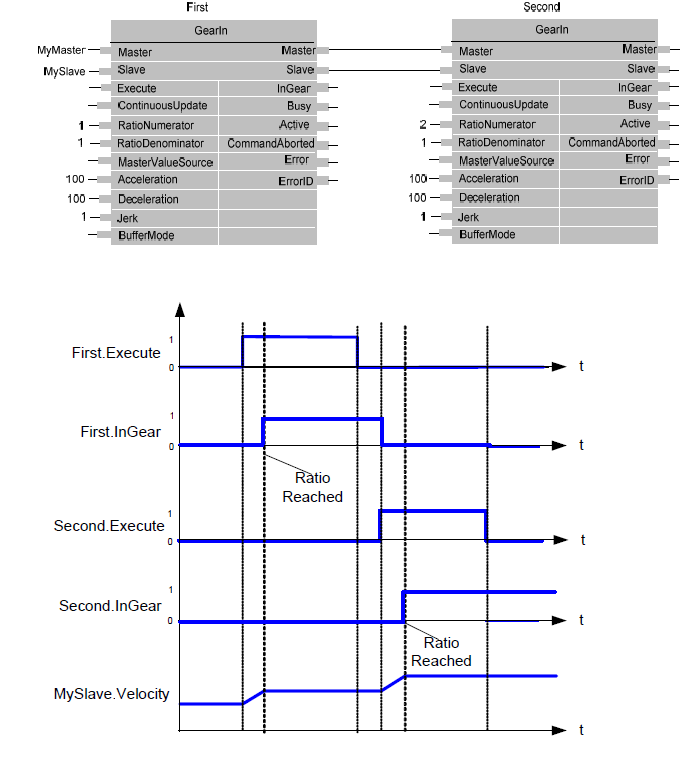

This function block commands a ratio between the velocity of the slave and master axis.

The slave ramps up to the ratio of the master velocity and locks in when this is reached. Any lost distance during synchronization is not caught up.

The gearing ratio can be changed while MC_GearIn is running by a rising edge at “Execute” or by using a consecutive MC_GearIn command without the necessity to MC_GearOut first

InGear is set the first time the ratio is reached.

After being InGear, a position locking is performed.

- Example of GearIn timing diagram

- InOut:

Scope

Name

Type

Comment

Input

ExecuteBOOLStarts the function block at rising edge

RatioNumeratorDINTGear ratio numerator, new value is updated only with rising edge of Execute input

RatioDenominatorDINTGear ratio denominator, new value is updated only with rising edge of Execute input

MasterValueSourceDecide to use the actual position or reference position of master axis

AccelerationLREAL[u/s°°2] Value of the acceleration (increasing energy of the motor), just applied until “insync” is reached. Range: >0. If value = 0, Acceleration will be equal to parameter paraMaxAccelerationAppl.If value > 0 and <= 1,Acceleration will be limited to 1.

DecelerationLREAL[u/s°°2] Value of the deceleration (decreasing energy of the motor), just applied until “insync” is reached. Range: >0. If value = 0, Deceleration will be equal to parameter paraMaxDecelerationAppl.If value > 0 and <= 1,Deceleration will be limited to 1.

BufferModeNot supported, default mcABORTING used

Output

InGearBOOLCommanded gearing completed

BusyBOOLThe function block is not finished

ActiveBOOLIndicates that the function block has control on the axis

CommandAbortedBOOLCommand is aborted by another command from other PLCopen function block

ErrorBOOLSignals that error has occurred within function block

ErrorIDError identification. For error details refer to Enumeration ERROR_ID

Inout

MasterReference to master axis

SlaveReference to slave axis