SKP_SlitterAutomaticKnifePositioning (FB)

FUNCTION_BLOCK SKP_SlitterAutomaticKnifePositioning

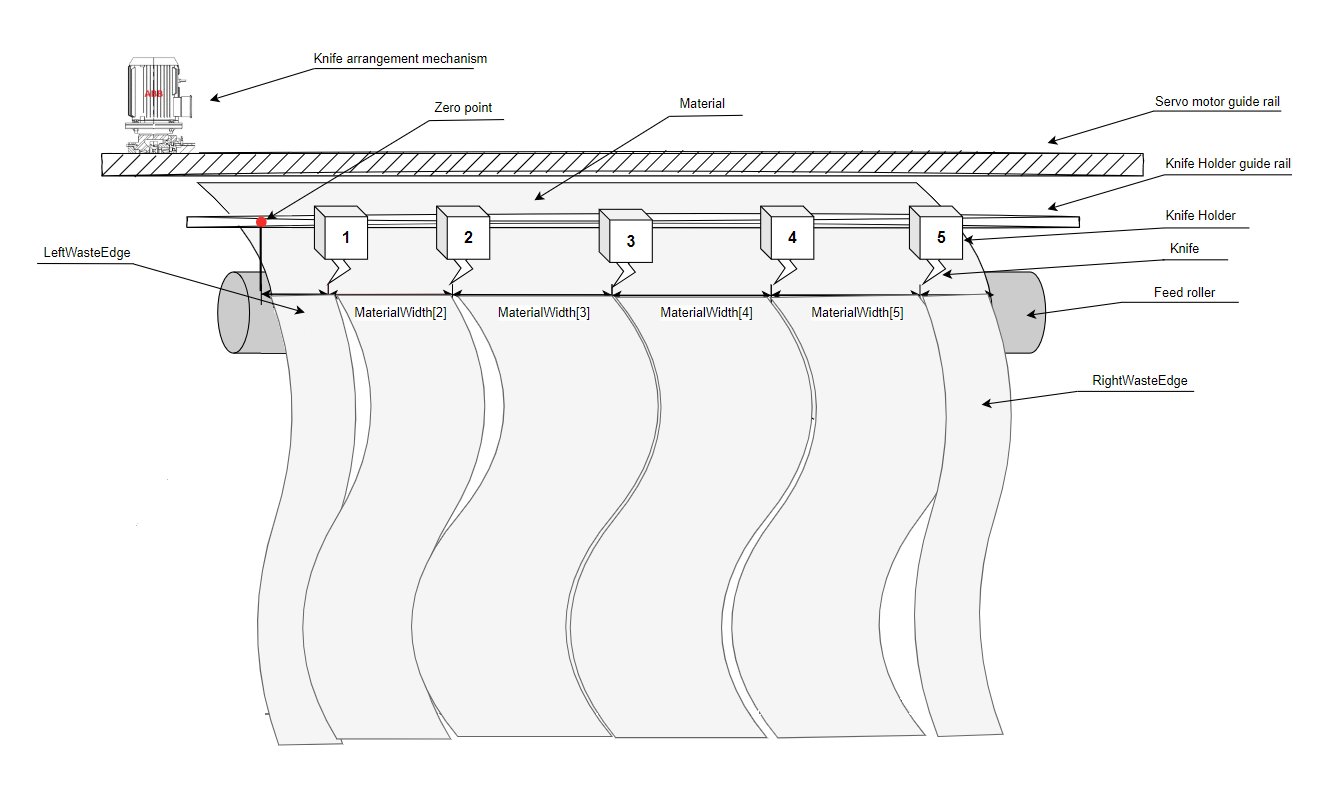

This application is used for the automatic positioning knife part of the slitting machine. By driving the mechanical device through a servo motor, the knives are arranged to achieve the goal of automatic positioning knife arrangement. Compared to traditional manual positioning knife, automatic positioning knife can greatly improve production efficiency.

Knife arrangement mechanism

The Knife arrangement mechanism includes a latch, a cylinder, and a servo motor. The cylinder is used to drive the latch to lock and release the knife, while the servo motor is used to drive this kinfe arrangement mechanism to position the knife.

Zero Point

Mechanical zero point of servo motor, reference point for all dimensions.

LeftWasteEdge

Left waste width input by the user.

RightWasteEdge

Right waste width input by the user

MaterialWidth[n]

The width of each required cutting material entered by the user.

Servo motor guide rail

The rack guide rail for the operation of the cutting servo motor is connected to it through gears.

Knife

The cutting tool used for cutting materials is generally made of metal material.

Knife holder

The knife is installed on the knife base, and there are also two cylinders installed on the knife base, one for locking and releasing the knife, and the other for lifting and lowering the knife.

Knife holder guide rail

The guide rail used to fix the knife holder can be moved through the guide rail.

Feed roller

Power rollers for material conveying, used to pull materials.

Note

For the MaterialWidth array, it take effect from MaterialWidth[2].

If the LeftWasteEdge is zero, the function block will not select a knife to cut the last LeftWasteEdge.

If the RightWasteEdge is zero, the function block will not select a knife to cut the last MaterialWidth.

For left to right mode,after a successful positioning for each knife,function block will recalculate the target position for next one, if this position can’t be reached,function block will report error.

- InOut:

Scope

Name

Type

Initial

Comment

Input

ExecuteBOOLStarts the function block at rising edge

KnifeMoveVelLREALMechanical and knife move together at this velocity.unit:mm/s

KnifeSearchingVelLREALMechanical to search knife at this velocity.unit:mm/s*

BackParkPosVelLREALMechanical back to home position at this velocity.unit:mm/s

KnifeAccLREALAcceleration for positioning knife velocity.unit:mm/s°°2

KnifeDecLREALDeceleration for positioning knife velocity.unit:mm/s°°2*

EPCOffsetLREALThe overall offset of the material relative to the home position.unit:mm

KnifeSelectionModeINT2

1:Left to right mode, The function block will select the kinfe from left to right according to the material width.2: Best path mode,The function block will calculate the shortest path for the servo motor to move based on the material width to select the knife.

KnifeDownModeBOOLMode of knife go down,False=manual ,True=auto

KnifeNumberINTNumber of all knives.must >=3 and <= 99

KnifeSpaceMinLREALMinimum safty space between two knives.unit:mm

ParkPositionLREALWhen procress is done,mechanical back to this position.unit:mm

KnifeHolderWidthLREALEnd position of knife,it is used to determine whether all material lengths are legal.unit:mm

EPCLimitLREALHigh limitation for edge position controller

LeftLimitSwitchBOOLLeft limit hardware switch of Mechanical

RightLimitSwitchBOOLRight limit hardware switch of Mechanical

KnifeLimitHighARRAY [1..99] OF LREAL

Upper limit of each knife travel.unit:mm.

KnifeLimitLowARRAY [1..99] OF LREAL

Lower limit of each knife travel.unit:mm

LeftWasteEdgeLREALLeft waste edge width.unit:mm

RightWasteEdgeLREALRight waste edge width .unit:mm

MaterialWidthARRAY [1..99] OF LREAL

The cutting width of each section of material input by the user.unit:mm

KnifeInitialPositionARRAY [1..99] OF LREAL

The initial position of each knife at the start of the process

KnifeOffsetPositionARRAY [1..99] OF LREAL

Fine adjustment value for each blade position

KnifeEnabledARRAY [1..99] OF BOOL

Available status of each kinfe, true means this knife can be selected and vice versa

KnifeLockPositionARRAY [1..99] OF BOOL

The locking position of knife feedback from the sensor

KnifeUnLockPositionARRAY [1..99] OF BOOL

The unlocking position of each knife feedback from the sensor

KnifeUpPositionARRAY [1..99] OF BOOL

The up position of each knife feedback from the sensor

KnifeDownPositionARRAY [1..99] OF BOOL

The down position of each knife feedback from the sensor

KnifeCheckSensorBOOLThe sensor feedback detects the kinfe signal

LatchUpPositionBOOLThe up position of the latch feedback from the sensor

LatchDownPositionBOOLThe down position of the latch feedback from the sensor

CylinderActionDelayTimeDINT500

Cylinder action delay time.unit:ms

Output

DoneBOOLShows the status of the function block. Done = TRUE if the execution is finished

BusyBOOLShows the status of the function block. TRUE when the instruction is acknowledged.

ActiveBOOLTrue when the axis is being controlled.

CommandAbortedBOOLCommand is aborted by another command from other PLCopen function block

ErrorBOOLSignals that error has occurred within function block

ErrorIDAC500_MotionControl.ERROR_IDAC500_MotionControl.ERROR_ID.MC_Ok

Contains the error code when there is an error.

AppErrorIDError identification. For error details refer to Enumeration ERROR_ID

ExtendLatchBOOLLever cylinder extend to take the knife

RetractLatchBOOLLever cylinder retract

KnifeSelectionARRAY [1..99] OF BOOL

Selection status of each knife,True=selected,False=Not be selected

KnifeLockARRAY [1..99] OF BOOL

Output signal of locking cylinder

KnifeUnLockARRAY [1..99] OF BOOL

Output signal of unlocking cylinder

KnifeUpARRAY [1..99] OF BOOL

Output signal of knife up cylinder

KnifeDownARRAY [1..99] OF BOOL

Output signal of knife down cylinder

KnifeActualPositionARRAY [1..99] OF LREAL

Actual position of knife when positioning knife process is done

TotalTimeTIMETotal time for the whole process

KnifeCylinderActionErrorARRAY [1..99] OF BOOL

Knife cylinder action error

Inout

AxisAxis_RefReference to axis

Structure: