|

This is the web edition of the original ⮫ AC500-S safety user manual, version 1.3.2. This web edition is provided for quick reference only. The original safety user manual must be used to meet functional safety application requirements. |

DANGER

The diagnosis data is not safety-relevant and, thus, shall not be used in safety application program for execution of safety functions.

- 1

-

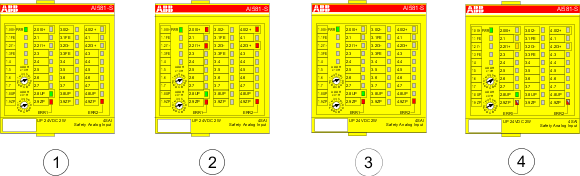

State 1 - Hardware reset and initialization

- 2

-

State 2 - LED test

- 3

-

State 3 - End state of initialization

- 4

-

State 4 - Parameterization is complete, but no PROFIsafe communication yet

Error messages

NOTICE

External errors (wiring or sensor errors) in safety I/O modules lead to the channel passivation ("0" values are delivered). As soon as an external error is fixed and this is recognized by internal safety I/O module tests, safety I/O module channels request an acknowledgment for their reintegration to the normal safety process control mode. The user can acknowledge such channels using dedicated channel bits(refer to Fig. 469).

Safety I/O module error messages are aggregated together with other module error messages in non-safety CPU.