|

This is the web edition of the original ⮫ AC500-S safety user manual, version 1.3.2. This web edition is provided for quick reference only. The original safety user manual must be used to meet functional safety application requirements. |

The input modules can be plugged only on spring-type TU582-S I/O terminal unit. The unique mechanical coding on I/O terminal units prevents a potential mistake of placing the non-safety I/O module on safety I/O terminal unit and the other way around. Basic information on system assembly is shown here.

⮫ “Mechanical planning and installation”

Installation and maintenance have to be performed according to the technical rules, codes and relevant standards, e.g., EN 60204 part 1, by skilled electricians only.

Assembly of DI581-S

DANGER

Hot plug and hot swap of energized modules is not permitted. All power sources (supply and process voltages) must be switched off while working with safety modules.

-

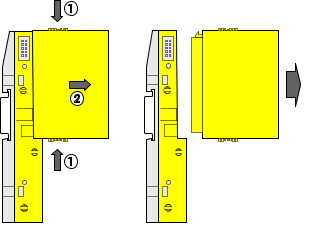

Fig. 416: Assembly instructions

Put the module on the terminal unit.

The module clicks in.

-

Then press the module with a force of at least 100 N into the terminal unit to achieve proper electrical contact.

Disassembly of DI581-S

-

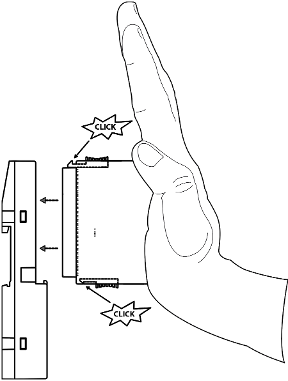

Fig. 417: Disassembly instructions

Press above and below, then remove the module.

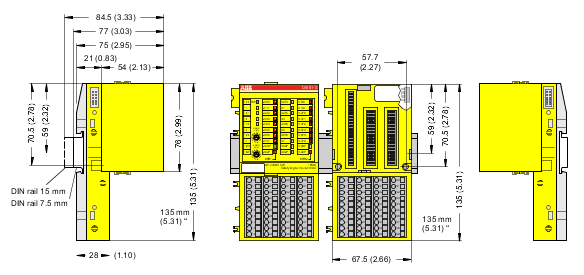

Dimensions

Electrical connection

NOTICE

The same TU582-S is used by all AC500-S safety I/O modules. If TU582-S is wired for DX581-S module with safety digital outputs and DI581-S or AI581-S modules are occasionally placed on this terminal unit, under no circumstances it is possible that safety digital output clamps on TU582-S become energized due to a wrongly placed DI581-S or AI581-S safety I/O modules.

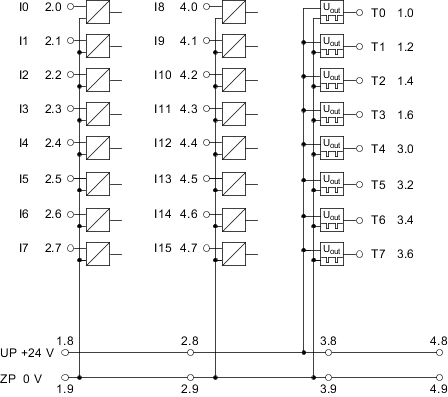

The electrical connection of the I/O channels is carried out using 40 terminals of the I/O terminal unit. I/O modules can be replaced without re-wiring the terminal units.

The terminals 1.8, 2.8, 3.8 and 4.8 as well as 1.9, 2.9, 3.9 and 4.9 are electrically interconnected within the I/O terminal unit and have always the same assignment, independent of the inserted module:

-

Terminals 1.8, 2.8, 3.8 and 4.8: Process voltage UP = +24 V DC

-

Terminals 1.9, 2.9, 3.9 and 4.9: Process voltage ZP = 0 V

The assignment of other terminals:

|

Terminals |

Signal |

Meaning |

|---|---|---|

|

1.0, 1.2, 1.4, 1.6, 3.0, 3.2, 3.4, 3.6 |

T0, T1, T2, T3, T4, T5, T6, T7 |

Connectors of 8 test pulse outputs T0, T1, T2, T3, T4, T5, T6, T7 |

|

2.0 ... 2.7, 4.0 ... 4.7 |

I0, I1, I2, I3, I4, I5, I6, I7, I8, I9, I10, I11, I12, I13, I14, I15 |

16 safety digital inputs |

|

1.8, 2.8, 3.8, 4.8 |

UP |

Process power supply +24 V DC |

|

1.9, 2.9, 3.9, 4.9 |

ZP |

Central process earth |

|

1.1, 1.3, 1.5, 1.7, 3.1, 3.3, 3.5, 3.7 |

Free |

Not used |

NOTICE

The process voltage must be included in the earthing concept of the control system (e.g., earthing the minus pole).

Examples of connections

Examples of electrical connections with DI581-S module and single channel Ix.