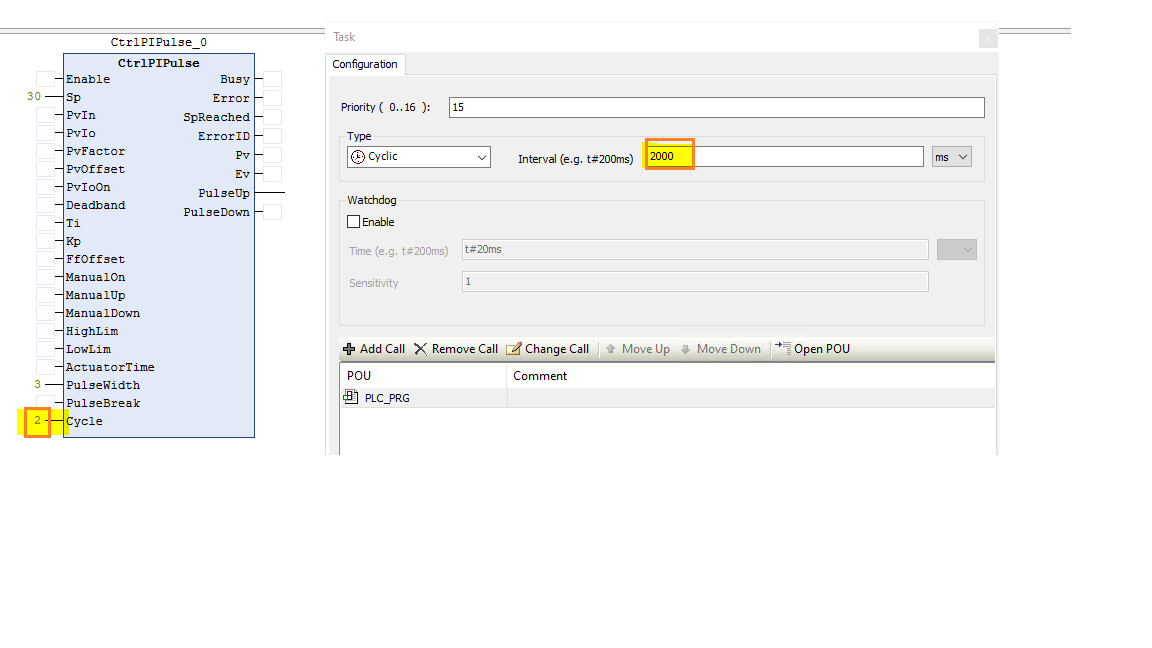

CtrlPiPulse (FB)

FUNCTION_BLOCK CtrlPiPulse EXTENDS AbbLConC3

This function block reacts as a PI step controller with digital pulse outputs to control two digital actuators. This is typically used in special HVAC applications with two different control properties e.g. heating and cooling.

Main features of the function block include-

Pulse output

Manual control mode

Input procesing

Feedback loop

Three step hysteresis relay

Pulse Generator

This Function Block performs as a PI step controller with digital pulse outputs to control 2 digital actuators.

The PLC task time (Unit: milliseconds) needs to be same as the “Cycle” (Unit :Seconds)input of the function block.

Note

The ActuatorTime needs to be > = 30 * Cycle, if not the ActuatorTime will be set to = 30 * Cycle internally

- InOut:

Scope

Name

Type

Initial

Comment

Input

SpREAL0.0

2: Set point input for PI step controller

PvInREAL0.0

3: Process variable input in floating point format

PvIoINT0

4: Process variable in IO format, PvIn=(PvIo*100/27648) * PvFactor + PvOffset

PvFactorREAL1

5: Process variable factor is used to adapt the process variable range

PvOffsetREAL0.0

6: Process variable offset is used to adapt the process variable range

PvIoOnBOOLFALSE

7: Turn on process variable input channel in IO format with PvIo

DeadbandREAL0.0

8: Dead band of Error variable, Deadband>=0

TiREAL10

9: Time response of the integrator (Unit: Second) 10000.0>= Ti >= 0.1

KpREAL1

10: Propotional gain input sets of PI controller

FfOffsetREAL0.0

11: Feed forward offset for Manipulated variable

ManualOnBOOLFALSE

12: Turn on manual mode for controlling PulseUp / PulseDown actuating signals: FALSE- Automatic mode, TRUE- Manual mode

ManualUpBOOLFALSE

13: When Manual mode is on, generate actuating signal for “PulseUp” output manually.This should not be in combination with ManualDown.

ManualDownBOOLFALSE

14: When Manual mode is on, generate actuating signal for “PulseDown” output manually.This should not be in combination with ManualUp.

HighLimBOOLFALSE

15: Connect to high limit of position feedback signal, HighLim = True means the actuator is at upper limit stop

LowLimBOOLFALSE

16: Connect to low limit of position feedback signal, LowLim = True means the actuator is at lower limit stop

ActuatorTimeREAL30

17: Motor actuating time is the time required by actuator to move from one limit stop to next limit stop.(Unit = Second), 10000 >= ActuatorTime > 0.1. Unit = Seconds.

PulseWidthREAL3

18: Minimum pulse width (Unit: Second) PulseWidth>=0.The PulseUp Output should have a logic “one” pulse width >= PulseWidth Input.

PulseBreakREAL6

19: Minimum pulse break (Unit: Second) PulseBreak>=0.The PulseDown Output should have a logic “zero” pulse width >= PulseBreak Input.

CycleREAL1

20: Cycle = PLC task cycle time (Unit: Second). Cycle>=0

Output

ErrorID2: Error Code.Error identifier if an invalid value was applied to an input

SpReachedBOOLFALSE

3: Controlling state of the PI step controller, SpReached=TRUE means process variable (PV) reaches set point (SP)

PvREAL0.0

4: Process variable output of PI step controller

EvREAL0.0

5: Error variable of the set point and the process variable

PulseUpBOOLFALSE

6: Pulse signal up, generates actuating signal to open actuating valve

PulseDownBOOLFALSE

7: Pulse signal down, generates actuating signal to open actuating valve