|

This is the web edition of the original ⮫ AC500-S safety user manual, version 1.3.2. This web edition is provided for quick reference only. The original safety user manual must be used to meet functional safety application requirements. |

NOTICE

The excerpts from an SVT checklist in this section are examples only and have been edited to fit. Your SVT checklist may look different depending on the versions of Automation Builder and SVT.

Carefully read through the SVT checklist and mark the corresponding checkbox for each section and question in the SVT checklist, if the result of your verification is positive.

-

Verify the project information section⮫ “How to verify the project information section”.

-

Verify each safety device section⮫ “How to verify the safety device sections”.

-

Verify the safety CPU section⮫ “How to verify the safety CPU section”.

-

Verify the libraries section⮫ “How to verify the libraries section”.

-

Verify the end of the SVT checklist⮫ “How to verify the end of the SVT checklist”.

If the result of your verification for at least one of manual checks in the SVT checklist is negative or not acceptable, make sure that safety configuration data is up-to-date. If the problems persist, contact ABB technical support for assistance.

Each section of the SVT checklist starts with a heading. The end of the SVT checklist is indicated with the text string:

How to verify the project information section

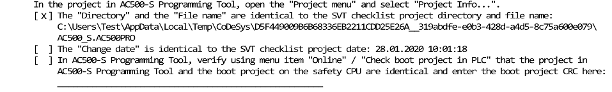

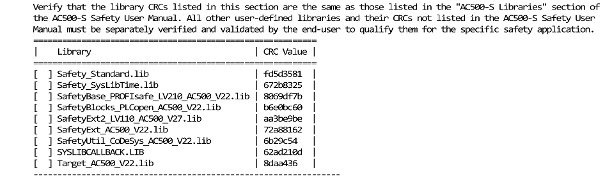

This section has general information on the SVT checklist. It begins with the time stamp and the version of SVT. Example of a project information section: Fig.479..

-

Verify that the automatic checks done by SVT have passed:

If the automatic checks generate errors, you get an error message⮫ “Errors in the automatic checks”:

-

In AC500-S Programming Tool, verify that the project information is correct. Mark a positive verification of an item with an "X" in the SVT checklist:

NOTICE

Mark the corresponding checkbox for each question in the SVT checklist as in the example above. You can mark the verified items into a printout or into the text file.

-

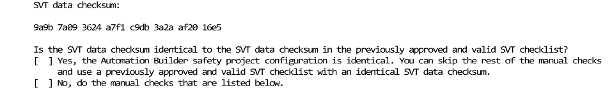

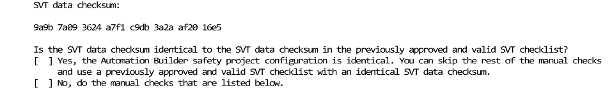

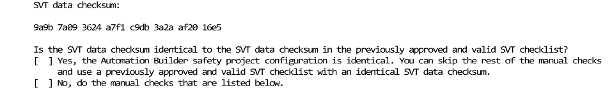

Read the data checksum for the whole SVT checklist.

Use this data checksum to verify changes to the entire SVT checklist.

Check if the data checksum is identical to the previous validated SVT checklist. If these SVT data checksums are identical, you do not need to do the manual checks.

If the data checksums are not identical or if you run SVT for the first time, continue with the manual checks in the SVT checklist.

-

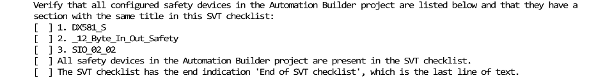

Verify that all of the safety devices in the Automation Builder project are listed in the SVT checklist.

If a safety device is not in the list, use “Create Safety Configuration Data” from the Automation Builder and run SVT again. Only configured and connected safety devices are listed in the SVT because all disconnected devices are handled outside of the given project.

After the line

End of SVT checklistoptional fields like date, signature, etc. are included. -

Continue to verify the contents of each safety device section.

How to verify the safety device sections

Each safety device has a separate section in the SVT checklist that begins with a heading with the name of the safety device. The information in each safety device section depends on the type of the safety device⮫ “Safety device sections”.

-

Verify that the automatic checks done by SVT for this safety device have passed.

If the automatic checks generate errors, you get an error message⮫ “Errors in the automatic checks”:

-

Read the data checksum for the safety device.

Use this data checksum to verify changes to the data for this safety device. If the data checksum is identical to a previously validated SVT checklist, the data for this safety device is identical and you can skip the manual checks for it. If the data checksums are not identical, repeat all of the manual checks for the safety device.

-

Verify the device type description. For 3rd party devices only, also verify the Module ID.

-

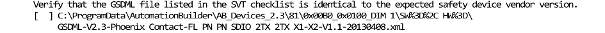

For 3rd party devices, verify that the version of the GSDML file shown in the SVT checklist is identical to the expected version from the safety device vendor.

-

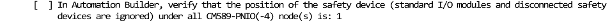

If applicable, verify that the position number of the safety device in the SVT checklist corresponds to its location in the safety project in Automation Builder. The position number for the given safety device can change if their CM589-PNIO(-4) nodes are moved in the project.

-

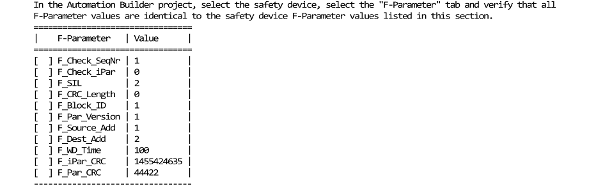

Verify the I/O mapping information for the safety device.

Note that “Data type” and “I/O” are listed for information only.

-

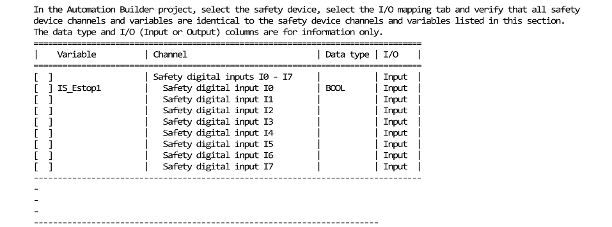

Verify F-Parameter values for the safety device.

NOTICE

According to PROFIsafe V2.6 protocol, the value "0" (zero) is not allowed for F-Parameter F_Par_CRC and will be automatically changed to "1". For this special case, a corresponding hint will be shown in SVT checklist. For futher details, contact ABB technical support.

Do these manual checks for each safety device in the SVT checklist. You can skip the sections for safety devices only if the data checksum for the safety device is identical to the previously validated and approved SVT checklist.

How to verify the safety CPU section

-

Verify that the automatic checks done by SVT for the safety CPU have passed.

If the automatic checks generate errors, you get an error message⮫ “Errors in the automatic checks”:

-

Read the data checksum for the safety CPU.

Use this data checksum to verify changes to the data for the safety CPU. If the data checksum is identical to a previously validated SVT checklist, the data for the safety CPU is identical and you can skip the manual checks for it. If the data checksums are not identical, repeat all of the manual checks for the safety CPU.

-

Verify the value of parameter "PROFIsafe startup timeout".

How to verify the libraries section

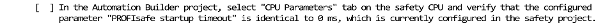

This section includes the library CRCs of the used safety libraries (Fig.484).

-

Read the data checksum for the libaries.

Use this data checksum to verify changes of the libraries. If the data checksum is identical to a previously validated SVT checklist, the libraries are identical and you can skip the manual checks for it. If the data checksums are not identical, repeat all of the manual checks for the libraries.

-

Verify that the library CRCs correspond to the AC500-S libraries⮫ “AC500-S libraries”.

How to verify the end of the SVT checklist

Verify that the SVT checklist ends with the line “End of SVT checklist”, and if so, mark the corresponding checkbox in the project information section (Fig.485).

Errors in the automatic checks

If there are errors in the automatic consistency checks, SVT shows this with an error message in the project information section of the SVT checklist.

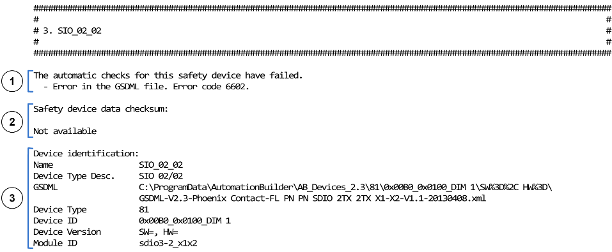

- 1

-

List of errors encountered by the automatic consistency checks done by SVT

- 2

-

List of remedies suggested by SVT to correct the causes of errors

- 3

-

No data checksum is given for the SVT checklist when there are errors

- 4

-

List of the safety devices indicates which safety devices have generated errors

NOTICE

If you cannot remedy all reported errors with the suggested remedies or otherwise, contact ABB technical support for assistance.

In addition to the project information section, each safety device section with errors has a corresponding message.

- 1

-

List of errors for this safety device with exemplary error codes

- 2

-

No data checksum is given for the safety device when there are errors

- 3

-

Device identification information to help in troubleshooting the issue

Summary of error messages

Possible errors generated by SVT:

-

General errors:

-

Internal error in the safety device N. 'XYZ'. For error codes, refer to the section for this safety device.

-

Internal error in safety project. Error code x.

-

Maximum number of 32 connected F-Devices has been exceeded.

-

-

Errors related to safety devices:

-

Internal error in the safety device. For error codes, refer to the section for this safety device.

-

Internal error in the safety device. Error code x.

-

Internal error in the safety device or GSDML file. For error codes, refer to the section for this safety device.

-

Internal error in the safety device or GSDML file. Error code x.

-

Internal error in F-Parameters. For error codes, refer to the section for this safety device.

-

Internal error in F-Parameters. Error code x.

-

Error in the GSDML file. Error code x.

-

Missing GSDML file.

-

-

Errors related to F-Parameters or channel mapping:

-

Internal error. Error code x.

-

Multiple mappings to an output are not permitted. Use either the parent element or sub-elements.

-

Possible remedies suggested by SVT to correct errors:

-

Reinstall the GSDML file of safety device N. 'XYZ' and update this device in Automation Builder.

-

Use either the parent element or sub-elements in the safety device N. 'XYZ'

-

Repeat the “Create Safety Configuration Data” command for your safety project in Automation Builder.

-

Delete or disconnect F-Devices in order not to exceed the maximum number of 32.