As mentioned in the beginning of the chapter, user can now configure EtherCAT master in AC500 CPU via CM579-ETHCAT communication module or in AC500-eCo Pro PLC’s via onboard ETH1 port.

In general, all EtherCAT settings are similar in both solutions but in CM579-ETHCAT user will have more settings tab than onboard EtherCAT. Based on which EtherCAT solution is used, user needs to also use the relevant libraries for diagnosis/SDO handling etc.

For CM579-ETHCAT use the library “AC500_EtherCAT” and for onboard EtherCAT use the library “ETCStack”. Both solutions are not identical, and user need to manually adapt the applications incase if moving from CM579-ETHCAT to onboard EtherCAT or vice versa.

CM579-ETHCAT

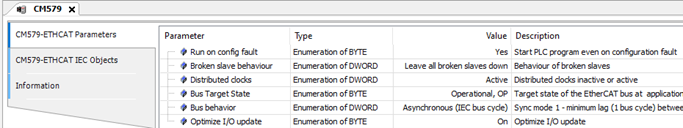

These are the settings specific to CM579-ETHCAT master and not valid for onboard EtherCAT. The label will normally CM579_ETHCAT this can be changed by the user but is normally left as default. If so, the name will be CM579_ETHCAT (CM579-ETHCAT).

In most cases these settings can be left at default but occasionally the user might need to change these to fit the application requirements.

-

“Run on Config Fault ” – As default it is set to “Yes” meaning the CM579-ETHCAT will not go into error and the PLC program will not go into stop if a slave is lost, this is beneficial as the PLC is then still available to handle other follow up actions. This can be changed if the user wants a configuration where a missing slave will prevent the PLC running.

-

“Distributed clocks” - As default it is set to “Active” which is a must if you want to use syncronised motion over EtherCAT.

-

“ Optimize I/O update” - As default it is set to “On” meaning that, consecutive I/O’s are merged in one block to optimize the performance.

ETHCAT_Master (EtherCAT-Master)

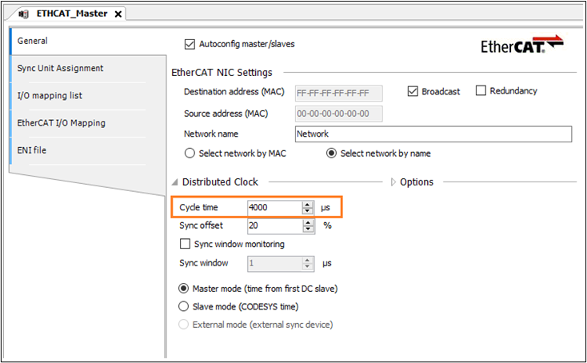

This second part of the EtherCAT master defines the specific settings that define the behavior of the EtherCAT operation and from here settings are similar in both CM579-ETHCAT and in onboard EtherCAT.

Onboard EtherCAT is only possible to configure it on PM5072 and PM5082 ETH1 port. It is recommended not to configure any other protocols on the EtherCAT configured ETH port.

The label will normally be in the format of ‘[name]( ETHCAT-Master)’ this can be changed by the user but is normally left as default. If so, the name will be ETHCAT_Master (ETHCAT-Master). The most important settings for this are mentioned below:

-

“Auto-config master/slaves” – As Default this is activated, this means the parameters are set automatically here in accordance with the default settings. This setting is recommended unless the user is very familiar with the setup of EtherCAT networks.

-

“Cycle time” - The default EtherCAT cycle time is 4000 μs but based on the application requirement, user can adapt the EtherCAT cycle time as as shown below.

EtherCAT cycle time will directly influence the PLC load. If your PLC load is higher than desired, please increase the cycle time or upgrade the PLC type.