For a detailed description of the mounting, disassembly and connection of the module, please refer to the system assembly chapter.

The connection is carried out by using a removable 7-pin terminal block. For more information, please refer to the chapter terminal blocks for AC500-eCo system. The terminal blocks are included in the module's scope of delivery and additional terminal blocks as spare parts can be ordered separately.

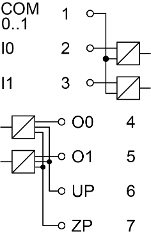

|

Terminal |

Signal |

Description |

|---|---|---|

|

1 |

COM 0 ... 1 |

Input common for signals I0 to I1 |

|

2 |

I0 |

Input signal I0 |

|

3 |

I1 |

Input signal I1 |

|

4 |

O0 |

Output signal O0 |

|

5 |

O1 |

Output signal O1 |

|

6 |

UP |

Process supply voltage UP +24 V DC |

|

7 |

ZP |

Process supply voltage ZP 0 V DC |

The internal power supply voltage for the module's circuitry is carried out via the connection to CPU. Thus, the current consumption from 24 V DC power supply at the terminals L+ and M of the CPU module increases by 10 mA per TA5110-2DI2DOT.

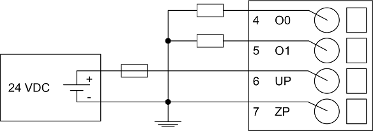

The external power supply connection is carried out via the UP (+24 V DC) and ZP (0 V DC) terminals.

WARNING

Removal/Insertion under power

The option boards are not designed for removal or insertion under power. Because of unforeseeable consequences, it is not allowed to plug or unplug option boards with the power being ON.

Make sure that all voltage sources (supply and process voltage) are switched off before you do the following:

-

Connect or disconnect any signal or terminal block.

-

Remove, mount or replace an option board.

Disconnecting any powered option board while energized in a hazardous location could result in an electric arc, which could create a flammable ignition resulting in fire or explosion.

Make sure that power is removed and that the area has been thoroughly checked to ensure that flammable materials are not present prior to proceeding.

NOTICE

Risk of damaging the PLC modules!

Overvoltages and short circuits might damage the PLC modules.

Make sure that all voltage sources (supply voltage and process supply voltage) are switched off before you begin with operations on the system.

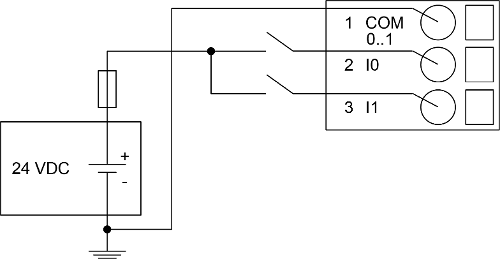

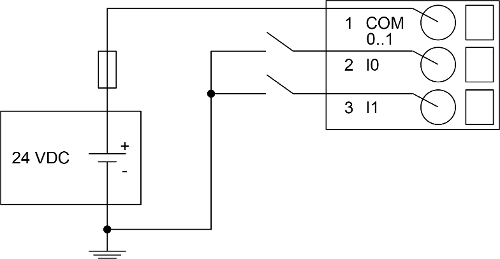

The digital inputs can be used as source inputs or as sink inputs.

NOTICE

Risk of malfunctions in the plant!

A ground fault, e. g. caused by a damaged cable insulation, can bridge switches accidentally.

Use sink inputs when possible or make sure that, in case of error, there will be no risks to persons or plant.

|

Sink inputs of TA5110-2DI2DOT |

Source inputs of TA5110-2DI2DOT |

|---|---|

|

|

NOTICE

Risk of malfunctions in the plant!

Only if L+/M of the CPU is available and the outputs are already configured in the AB program, the outputs will switch on as soon as the UP/ZP is available.

This must be considered in the application planning.

NOTICE

Risk of damaging the I/O module!

The outputs are not protected against short circuits and overload.

-

Never short-circuit or overload the outputs.

-

Never connect the outputs to other voltages.

-

Use an external fuse for the outputs.

The module provides several diagnosis functions⮫ Further information.

The meaning of the LEDs is described in the section State LEDs ⮫ “State LEDs”.