|

This is the web edition of the original ⮫ AC500-S safety user manual, version 1.3.2. This web edition is provided for quick reference only. The original safety user manual must be used to meet functional safety application requirements. |

In this chapter, application examples based on PLCopen Safety POUs are presented with the main goal to give an explanation on how PLCopen Safety POUs can be used in typical safety applications. Examples are used from⮫ [6] with a permission from PLCopen organization.

Initialization procedures for handling PROFIsafe start-up behavior and AC500-S specific POUs are not listed in these examples, but have to be included in the final safety application programs.

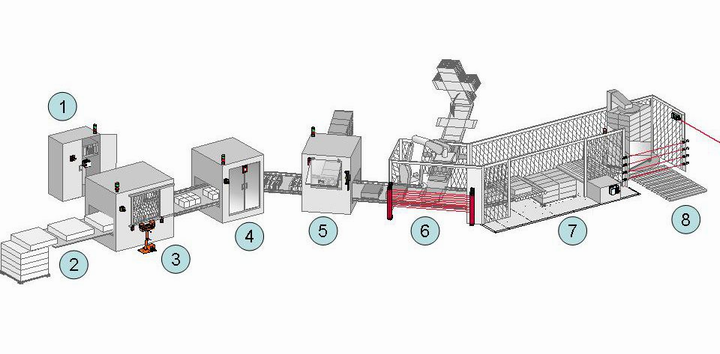

As an example of the usage of safety functions, the following production line is used. The PLCopen FBs described below can be used to easily realize the safety application program for this production line.

1

Centralized switchgear cabinet, including the safety related part of the control system where the safety related function blocks are running.

2

Infeed of material. In this part, no special safety related functions are used. However, safety functionalities like muting to separate between products and persons could be used.

3

Cutting of the material. For manual control, a two hand control safety function (unit is in front of the machine) is added combined with a 2-fold door monitoring system (attached to the door on the machine)

4

Automatic printing station, with door monitoring as safety function in case of service access (attached to the door on the machine)

5

First cartoning machine with door monitoring as safety function in case of service access (attached to the door on the machine). Sometimes, the manual operation is necessary. In this case, the operator can run the machine with a safely limited speed controlled by an enabling device which, when released, initiates a safe stop.

6

Second cartoning machine, guarded by an electro-sensitive protective equipment, ESPE. In this case, it is a light curtain.

7

Palletizing function, guarded by safety mats. This functionality could be coupled to the ESPE safety function.

8

Foil wrapping station of the palletized products with an exit of the production line. This area is safeguarded by several combined light beams, coupled to the ESPE safety function.

In addition, every station is equipped with an emergency stop.