The pressure control mode follows this sequence of operation:

-

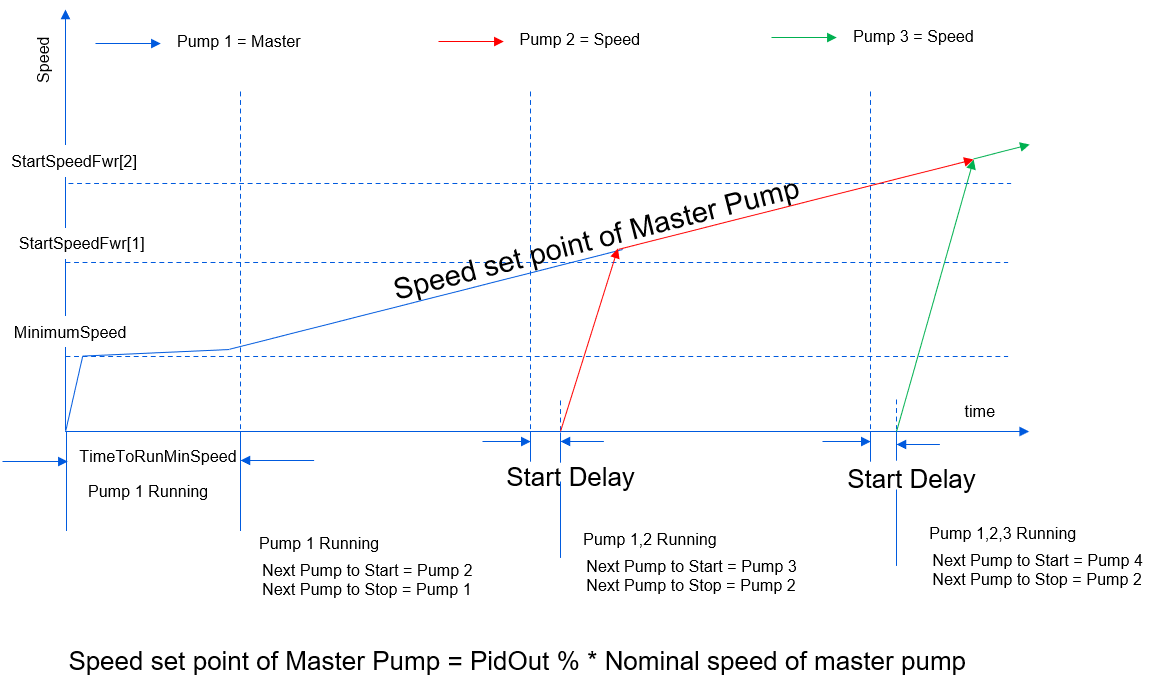

When the process is started, the first pump runs at “MinimumSpeed” for the time defined in the “TimeToRunMinSpeed” duration. With this process the pipe starts filling gradually and then the normal operation of PID control takes over.

-

The PID compares the required pressured and the actual pressure to generate the output in terms of percentage. This output must be connected to the function block “PmpPressureDistributor”.

-

The function block “PmpPressureDistributor” receives the “PidOut”. The distributor converts the PID output in terms of speed for the master pump.

-

The function block “PmpSequenceGen” has the “MasterPump” information.

-

The “PidOut” is scaled in terms of speed in this method:

Speed reference of “MasterPump” = (“NominalSpeed” of “MasterPump”) * (“PidOut”/100)

-

As the PID output increases, the speed of the master pump increases. A higher PID output indicates a high demand. In case one pump is not able to cater the requirement, then more pump (followers) are needed to start and supply water to maintain the pressure.

-

If speed reference of the “MasterPump” increases such that it is more than the “StartSpeedFwr[1]”, then the first follower in the network will start. The information about which pump to start comes from function block “PmpSequenceGen” at the output “NextPumpToStart”.

-

If the speed reference of the “MasterPump” increases further such that it is more than “StartSpeedFwr[2]”, then second follower pump starts. This sequence is followed till there is an increase in demand. See the timing diagram below.

-

Start Delay: Delay time [s] to start the next pump

-

-

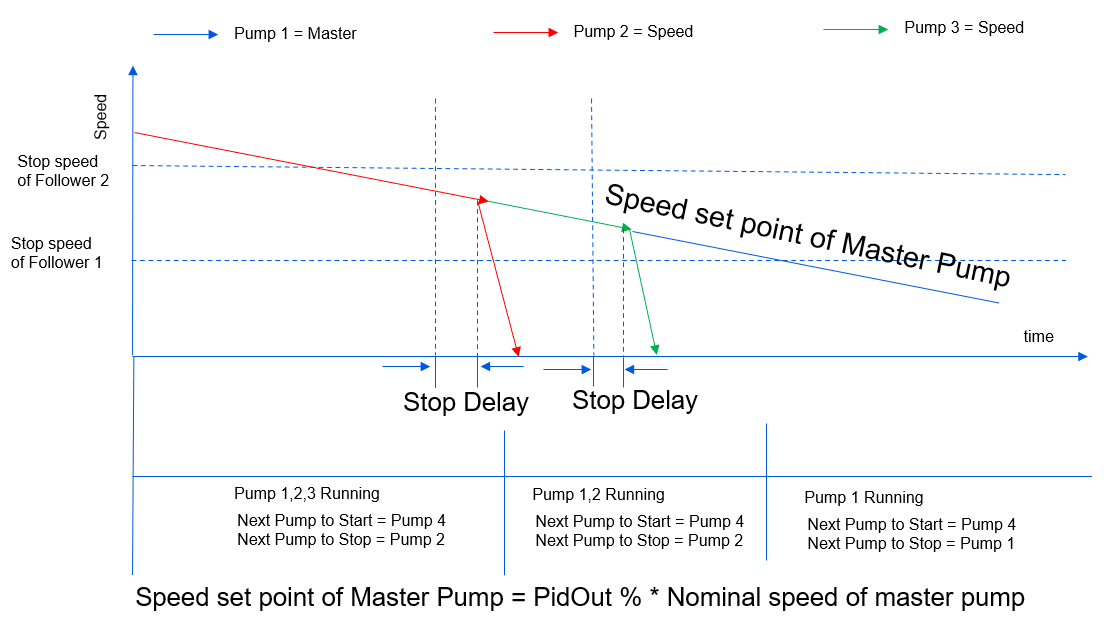

Similar when the demand decreases, the speed reference of master decreases. See the timing diagram below. As the speed reference of the master pump goes below “StopSpeedFwr[1]”, the first follower stops. The ID of next pump to stop comes from “PmpSequenceGen” as “NextPumpToStop”. If the speed reference of the “MasterPump” decreases further such that it is less than “StopSpeedFwr[2]”, then second follower pump stops. This sequence is followed till there is a decrease in demand.

The follower pumps in the above figure is considered to be in the “FollowerMode”= 1, copy master speed. They can also run at their individual speed if “FollowerMode”= 2, fixed speed.

-

Stop Delay: Delay time [s] to stop the next pump

-